Basic Wood Science

Tree Parts

There are more than 5,000 kinds of woods in the world and selecting wood as a building material is an environmentally friendly choice having a bigger impact than recycling.

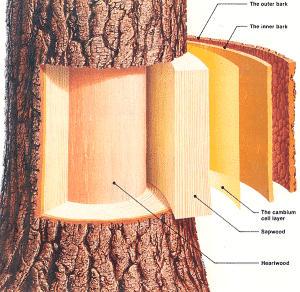

Wood comprises sapwood and heartwood. Sapwood is the living, outermost portion of a woody stem or branch, while heartwood is the inner wood at the center of the trunk, which often comprises the majority of a stem’s cross-section and is darker in color and filled with natural biochemicals.

Wood Classification

There are also major wood classifications that one considers when finishing wood – is it a hardwood, softwood, or modified wood? You can always use this resource to research wood types and see the inherent color of a wood species in addition to its rot resistance, uses, and sustainability to name a few: https://www.wood-database.com/

In general, hardwood comes from a deciduous tree which loses its leaves annually and softwood comes from a conifer, which usually remains evergreen. Hardwoods tend to be slower growing, and are therefore usually more dense. Hardwoods include eucalyptus, beech and blackwood.

A hardwood is an angiosperm, a plant that produces seeds with some sort of covering such as a shell or a fruit. Angiosperms usually form flowers to reproduce. Birds and insects attracted to the flowers carry the pollen to other trees and when fertilized the trees form fruits or nuts and seeds. Softwood trees are known as a gymnosperms. Gymnosperms reproduce by forming cones which emit pollen to be spread by the wind to other trees. Some examples of softwood include pine, redwood, douglas-fir, cypresses and larch.

Modified woods undergo a chemical or heated treatment, such as Accoya or Thermally Modified Wood, for added durability and longevity features.

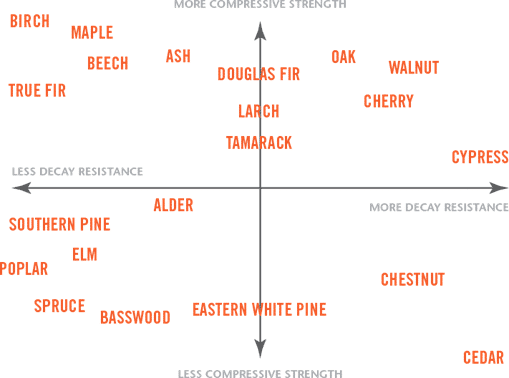

With variety of woods comes various characteristics related to colour, strength, density, decay resistance to name a few. In other words, the wood species is the primary factor in determining the surface properties of wood. Other wood properties, such as knots, juvenile wood, and extractives, also affect wood finishing.

That is why the selection of wood for different uses is important – and for Sansin dealers, that is why it’s important when recommending a coating system to find out what wood the customer is using for the deck, siding, door, etc. And, when possible, obtain a photo of the project to be finished to assess the state and type of wood.

Lumber Cut and Shrinkage

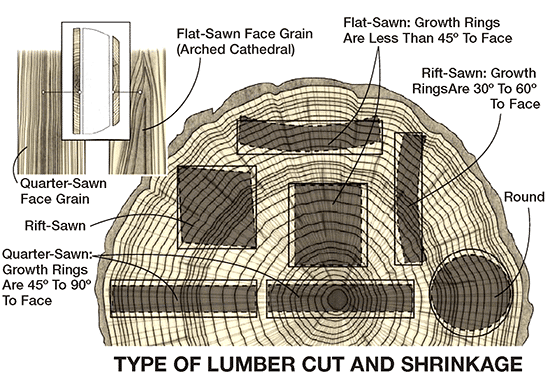

Finally, once a type of wood is selected, the type of lumber cut impacts shrinkage factors and finishing.

So, in addition to age, heartwood vs. sapwood, you want to consider the lumber cut and shrinkage.

Shrinkage has to do with moisture content and the location of the cut lumber. As the log is converted (sawn) into boards, water leaves the wood by surface evaporation. As water is evaporated at the surface, interior moisture migrates to the surface and is also evaporated. This is the natural drying process.

Generally, wood shrinks more around its circumference than it does across its radius. If you think of the annual growth rings, the shrinkage ‘along the rings’ is about twice as much as the shrinkage ‘between the rings’. Therefore, shrinkage is not equal in both directions. It is this unequal shrinkage that causes distortion in wood as it dries.

For example, plain sawn (flat sawn) is more prone to cupping since it is a tangential cut, while Quarter-sawn wood is more stable expands and contracts less (and is therefore more desirable). Wood shrinks tangentially.

So be aware of the lumber cut, and be aware of the moisture content of wood. Sansin coatings help to minimize shrinking and swelling which can cause distortion and checking since it protects the wood, while allowing the wood to breathe and normalize its moisture content slowly.

Learn more about Wood Cuts and Shrinkage here.

Sansin Tip:

When working on a typical house deck, look for the BARK SIDE and the PITH SIDE. The bark surface does not splinter or roughen as much as pith side. Place the bark side up when possible. If it has wane (an edge along the length that is missing) then the converse is true – place the bark side down.

Water-borne Technology

History of Coatings

History indicates that builders have been treating wood for almost as long as they have used it as a building material. Wood tar – the resin that results from heating wood – has been traced back to the Iron Age in Scandinavia, and the Romans used tar to protect the wooden hulls of their ships. Linseed oil, also known as flaxseed oil, has been used for hundreds of years to protect and maintain wood.

However, some of the more traditional oils, like linseed oil, lacks UV protection, creates a golden hue that is sometimes undesirable, and can even support the growth of mildew. Furthermore, linseed oil is high in volatile organic compounds (VOCs), which contribute to smog and ozone depletion. Petroleum-derived solvents are even more environmentally detrimental, requiring large amounts of energy to extract and ship the petroleum and then process it into solvents.

Over the last three decades, the industry wanted – and consumers and regulators were increasingly demanding – coatings that reduced the impact on the environment while also allowing for easy clean up and maintenance along with faster drying times. The 1990 New Clean Air Act by the Environmental Protection Agency (EPA) required manufacturers to decrease the number of VOCs in their finishes.

Learn more about VOCs here.

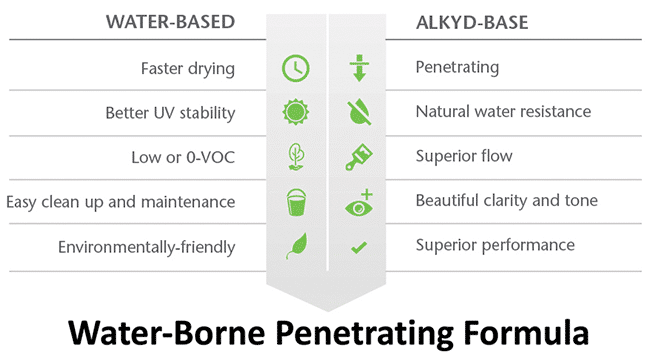

Initially, water-based stains entered the market but became unpopular as they didn’t have the clarity, flow, penetration, water repellency or performance that users expected from an oil-based finishing product. Ultimately, water-based coatings let finishers down, and some coaters insisted on oil-based stains, despite the higher toxicity.

Water-borne introduced

Eventually, newer water-borne technology was developed that utilized modified natural resins, but used water to carry the finish into the wood. In this way, water-borne finishes were now able to deliver on the performance and beauty of traditional oil-based products while living up to their environmental promises. In addition to reducing environmental toxins, water-borne finishes offer UV stability and are a more user-friendly option with easy clean-up and maintenance.

Introduced by Sansin in 1986, penetrating, water-borne technology would become the fundamental formula for bringing a high-performance, low VOC and less toxic line of wood stains and finishes to market.

The water-borne approach from Sansin allowed users who liked the flow and clarity of traditional oil to get this experience with the low VOCs, faster drying and easy clean up and maintenance of water-based stains.

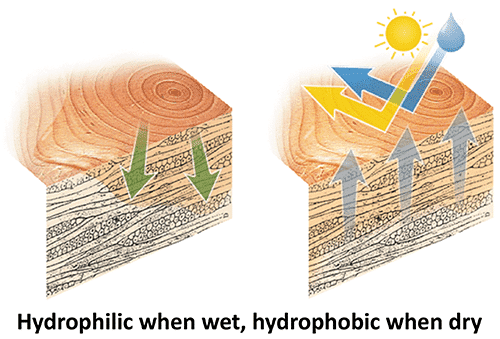

Another benefit of Sansin’s water-borne products is that they are hydrophilic when wet, and hydrophobic when dry. This is important so that the product dives into the wood for protection at the cellular level, but when dry, it will repel water and protect against UV, all the while allowing the wood to naturally breathe and not trap any moisture

It is important to note that the terms “water-borne” and “water-based” are often incorrectly used interchangeably. In truth, the technologies are very different. For this reason, applicators and contractors – especially those who have a history with the troublesome water-based finishes – need to understand the differences. In short, it is no longer necessary to use traditional oils and solvents to achieve the desired look and protection, especially if the project has an environmental scope in terms of toxicity, VOCs and the health of applicators and customers.

Watch Video to learn more about waterborne stains: 6:34 to 7:00

Cleaning, Sanding and Application

Prepping the Wood for Finishing

Wood is a beautiful, durable and versatile material, whether it is being used for millwork, cabinets, furniture, decking, or home construction. To help ensure lasting beauty and protection on your next wood project, preparation is key to maximizing wood finish performance.

As you learned in previous lessons, Sansin water-borne stains are meant to penetrate the wood surface, so avoiding proper preparation such as sanding and cleaning will likely lead to disappointing results.

Key steps to preparation:

1. Cleaning the Wood Surface

If needed, wash the wood surface to remove dirt and residue. Plain water can be sufficient, but technique is key. Use a 3500 psi power washer with a 15-degree tip at 4.5 gallons per minute. The technique is to clean the wood without eroding it. This technique is best described as sweeping over the wood (in a semi-circle motion) in quick passes, causing the 15-degree tip to come to within 4-5 inches from the surface and receding quickly (sweeping away at the end/exit). Like sweeping a broom but exiting the surface to prevent eroding from excessive pressure and flow.

If you need to remove more obstinate residue such as mildew, mold or a previous stain, Sansin offers three cleaners to tackle those circumstances – to be used before sanding.

This all purpose, biodegradable cleaner can be diluted up to 12x and used on interior and exterior wood (as well concrete and masonry) to remove dirt, mold, mildew water and iron stains.

Wood Wash

Restores weathered wood to a clean, natural state without raising the wood grain. You must use a neutralizer after use to neutralize and brighten wood.

This option removes paints, stains in as little as 20 minutes. This is used with a wood lightener pouch to neutralize and brighten wood, helping the wood accept the coating

2. Sanding the Wood Surface

No matter the type of wood you are working with, proper sanding is a critical first step to remove any mill glaze from smooth wood, in order to open the pores, and allow the finish to penetrate. Use the proper equipment (variable speed, random orbital sander) to evenly sand exterior wood surfaces with 60-80 grit paper, and then use compressed air or a vacuum to remove the dust. Sanding opens the pores and removes contaminants to improve coating adhesion.

Here are some tips from one of our recommended sanders to show more about how to use an orbital sander and the benefits.

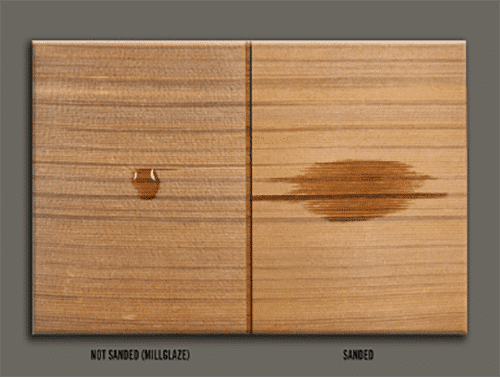

Fast Fact: Mill Glaze and Sanding

Sanding removes the mill glaze that is left behind after the wood is processed at the saw mill. This mill glaze creates a barrier to the penetration of the finish. Watch this video to see how sanding makes a significant difference in finish penetration – and as a result, finish performance.

3. Sanding and Impact on Durability

To further highlight the impact of sanding before coating. This field test demonstrates the outcome of finished wood after 2 years in a fully exposed setting. The top half of the boards were sanded, while the bottom half was not sanded. Ten different water borne, water based and solvent wood finish formulas were applied (the middle section is all one formula and used as control measure). One thing is very clear: most finishes perform poorly on non-sanded wood.

Finish Application

Application Best Practices

Stir the water-borne product well (and continue to do so throughout the application process), ensuring there are no solids left on your stir stick. Test the color on a small, inconspicuous section of the wood to confirm you are getting the look you want and the penetration the finish needs.

Depending on the surface area you are coating, using a sprayer could be the fastest, easiest way to apply the product. For vertical surfaces, use a slightly upward angle and work section by section to apply the finish to the point of refusal from the bottom to the top. Use a high-quality brush to wipe away excess product, drips or runs. Follow the manufacturer’s directions on drying time before applying additional coats.

Watch these videos to learn more about application best practices for siding and decks.

Siding:

Decking:

A Word on Weather: Generally, do not apply if rain or near freezing temperatures are expected, do not apply in heat of day or direct sun. Ideal temperature is 21C at 50% relative humidity.

Be Proactive About Maintenance

The durability of a wood finish depends on many factors, including surface preparation, proper application, exposure to UV and moisture, the color of the finish (the darker the pigment, the more protection it offers), and the quality of the wood, just to name a few. As the maintenance time approaches, examine the surface of the wood every six months to check on the status of the coating. The takeaway here is to apply a maintenance coat before more serious corrective action is needed.

Waiting one season too long can make all the difference.

It is important to inspect the surface carefully from time to time and look for even the smallest signs that maintenance is needed. For example, a deck may have a high traffic area that leads from the back door to a pool or a much-used lawn area. Alternatively, perhaps a couple of areas see excessive wetting from sprinklers.

Other design issues might cause trouble. Downspouts or a clogged evestrough (gutter) can cause a waterfall to constantly pour water onto an area of the deck during times of precipitation. Other areas may get more wear from higher than normal exposure to rain, snow, sun or foot traffic. Remember, excessive wetting (moisture) is much more problematic than UV exposure. Wetting causes the wood to swell and then shrink while drying. From this natural expansion and retraction, little cracks will form as the wood cycles through these extreme conditions. This causes the wood to discolor and the coatings to wear prematurely. Designing the landscape and roof drainage to avoid excessive wetting can help reduce these extremes and extend maintenance cycles.

Fast Fact: Sansin offers a proactive maintenance program, called Sansin Care. Sansin Care is a professional, proactive maintenance assistance program for large residential/commercial and architectural projects that have been completed. Building managers or owners receive guidance on how they can maintain the durability and beauty of their wood structure and maximize their investment in a protective coating. To learn more, visit https://www.sansin.com/resources/sansin-care/